Distributed Control Architecture for smart surfaces

A

distributed control architecture is needed to perform part recognition

and close-loop control of the Smart Surface. This architecture is based

on decentralized cells able to communicate with their four neighbors

thanks to peer-to-peer links. Various original algorithms have been

proposed to reconstruct, recognize and convey the object levitating on

the Smart Surface.

A

distributed control architecture is needed to perform part recognition

and close-loop control of the Smart Surface. This architecture is based

on decentralized cells able to communicate with their four neighbors

thanks to peer-to-peer links. Various original algorithms have been

proposed to reconstruct, recognize and convey the object levitating on

the Smart Surface. Experimental results show that each algorithm does a good job for itself and that all the algorithms together succeed in sorting and conveying the objects to their final destination. Read more...

Video: Experimental validation (8 MB mp4 file)

Distributed Discrete State Acquisition and Concurrent Pattern Recognition

In

order to differentiate the parts put on top of the Smart Surface,

algorithms of distributed state acquisition and concurrent pattern

recognition have been developed. These algorithms have been tested in a

multithreaded Java Smart Surface Simulator, SSS, which runs on

multicore machines. Read more...

In

order to differentiate the parts put on top of the Smart Surface,

algorithms of distributed state acquisition and concurrent pattern

recognition have been developed. These algorithms have been tested in a

multithreaded Java Smart Surface Simulator, SSS, which runs on

multicore machines. Read more...Video: Smart surface simulator (9 MB wmv file)

Decentralized Reinforcement Learning

Distributed-air-jet

MEMS-based systems have been proposed to manipulate small parts with

high velocities and without any friction problems. The control of

distributed-air-jet systems is very challenging and usual

approaches for contact arrayed system don't produce satisfactory

results. We investigate reinforcement learning control approaches in

order to position and convey an object. Reinforcement learning is a

popular approach to find controllers that are tailored exactly to the

system without any prior model. We show how to apply reinforcement

learning in a decentralized perspective and in order to address the

global-local trade-off. Read

more...

Distributed-air-jet

MEMS-based systems have been proposed to manipulate small parts with

high velocities and without any friction problems. The control of

distributed-air-jet systems is very challenging and usual

approaches for contact arrayed system don't produce satisfactory

results. We investigate reinforcement learning control approaches in

order to position and convey an object. Reinforcement learning is a

popular approach to find controllers that are tailored exactly to the

system without any prior model. We show how to apply reinforcement

learning in a decentralized perspective and in order to address the

global-local trade-off. Read

more...Calibration of the Smart Surface

The

number of sensors that have to be embedded in the Smart Surface is a

parameter that has to be taken into account when designing the hardware

part of the Smart Surface. The Sensor

The

number of sensors that have to be embedded in the Smart Surface is a

parameter that has to be taken into account when designing the hardware

part of the Smart Surface. The SensorNetwork Calibrator (SNC) is a simulation framework which allows to parameterize the Smart Surface and to determine the number of sensors required on top of the Smart Surface. Read more...

Distributed Shape Differentiation

One

of the aims of the processing unit embedded in each cell of the Smart

Surface is to recognize the shape of the part that is put on top of the

smart surface. This recognition or more precisely this differentiation

is done through a distributed algorithm that is called a criterion. In

order to test exhaustively the efficiency of different differentiation

criteria, in terms of differentiation efficiency, memory and processing

power needed, a software framework called ECO (Exhaustive Comparison

Framework) has been developed. Read more...

One

of the aims of the processing unit embedded in each cell of the Smart

Surface is to recognize the shape of the part that is put on top of the

smart surface. This recognition or more precisely this differentiation

is done through a distributed algorithm that is called a criterion. In

order to test exhaustively the efficiency of different differentiation

criteria, in terms of differentiation efficiency, memory and processing

power needed, a software framework called ECO (Exhaustive Comparison

Framework) has been developed. Read more...Multi-domain Simulation using VHDL-AMS

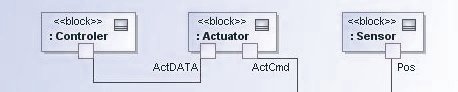

We

propose advance methods of behavioral modeling, allowing both easy

development and faster simulation for better integration of arrayed

MEMS into systems. Design and simulation are produced by solverbased

cost-effective solution using VHDL-AMS. A hierarchical circuit-level

design methodology has been followed to model and simulate a MEMS

array-based smart surface applied in air-fluid environment for 2-D

contactless micromanipulation. Using a V-shaped-based design approach,

a top-down VHDL-AMS-based modeling has been first achieved with

behavioral, structural behavioral, and component models, which include

a MEMS-based pneumatic microactuator. Then, a modeling bottom-up

approach has been developed to validate our design by comparing

simulations and experiments of the distributed surface. Read more...

We

propose advance methods of behavioral modeling, allowing both easy

development and faster simulation for better integration of arrayed

MEMS into systems. Design and simulation are produced by solverbased

cost-effective solution using VHDL-AMS. A hierarchical circuit-level

design methodology has been followed to model and simulate a MEMS

array-based smart surface applied in air-fluid environment for 2-D

contactless micromanipulation. Using a V-shaped-based design approach,

a top-down VHDL-AMS-based modeling has been first achieved with

behavioral, structural behavioral, and component models, which include

a MEMS-based pneumatic microactuator. Then, a modeling bottom-up

approach has been developed to validate our design by comparing

simulations and experiments of the distributed surface. Read more...